LB-Co-extrusion dûbele laach wpc profyl extrusion line

Raw materiaal + hout macht + additief → mingen → granulating → konyske twin-screw extruder → profyl extrusion mal → koele moulding die → fakuüm kalibraasje stipe → haul-off → cutter → rek → klear produkt

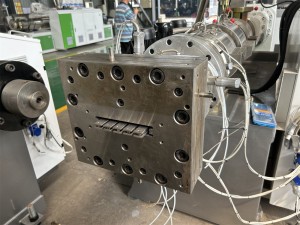

1> Conical Double screw extruder: SJSZ-65/132

2> WPC PP/PE/PVC-finsters, doarren, fencing, decking, plinten, flierprofylfoarm

3> Vacuum kalibraasjesysteem

4> Haul off masine

5> Snijmasine

6> Discharge beugel

7> Mixer

8> Embossing masine

| Extruder Model | SJZ55/110 | SJZ65/132 | SJZ80/156 | SJZ92/188 | ||

| Motor macht (kw) | 22 | 37 | 55 | 110 | ||

| Produkt breedte | 200 | 240 | 300 | 600 | 900 | 1200 |

| Vacuum macht | 4kwx1 | 5.5kwx1 | 5.5kwx1 | 5.5kwx2 | 5.5kwX1 7.5kwX1 | 5.5kwX1 7.5kwX1 |

| wetterpomp | 2,2 kw | 2,2 kw | 4 kw | 5 kw | 7 ,5kw | 7 ,5kw |

| Hauling snelheid | 0-5m/min | 0-5m/min | 0-5m/min | 0-3 m/min | 0-2,5 m/min | 0-2,5 m/min |

| Kapasiteit (kg/h) | 70 kg/h | 110 kg/h | 110 kg/h | 170 kg/h | 300 kg/h | 300 kg/h |

| Nettogewicht (kg) | 3000 | 5000 | 6500 | |||

As grûnstof PE of PP is, moatte jo houtpoeder + PP / PE-dieltsjes byinoar mingje, en set se dan yn pelletisearjende line, krije úteinlik definitive houten plestikpellets.